A visit to Enigma Heaven

A few days ago my friend Jim emailed to tell me he had a couple

of interesting Enigma cipher machines in his shop that he was repairing for the National Crypotlogic Museum. He invited me over for a visit and to check them out.

Below are some photos that Jim took while I was there.

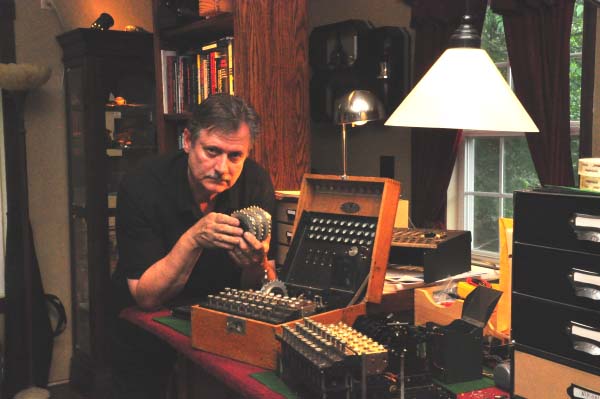

Here I am checking out the rotors from one of the machines.

The one on my right is a 'T' machine or TIRPITZ, made by the Germans for the Japanese. It was captured before it could get to them.

The machine still in it's wooden case is an early 'A' machine that was made in the mid 30s for commercial use by banks.

This is my friend Jim Oram, the Enigma Master himself.

Jim makes some incredible, unobtainium parts for Enigmas.

Jim is currently working with the Graveyard of the Atlantic Museum on their Enigma that was retrived from a U Boat U-85 that sunk off the coast of

North Carolina.

He also makes regular trips to Washington DC to the National Cryptologic Museum to make repairs on their Enigma machines.

To visit Jim's Enigma parts web page "click" on his photo.

Below are some photos that Jim permitted me to use to

show what the rotors from U-85 look like.

Jim makes perfect replacement rotors for Enigmas.

"Photos by Jim Oram, use thereof granted exclusively to Ron Lawrence"

This is the U-85 rotor set for Enigma machine # M-2946

This is M-2946 being rebuilt, note the new rotors have been installed.

This is M-2946 being rebuilt, note the new rotors have been installed.

The M2946 ZAMAK Rotor parts have disintegrated over the 60+ years under water in the U85's Radio Room.

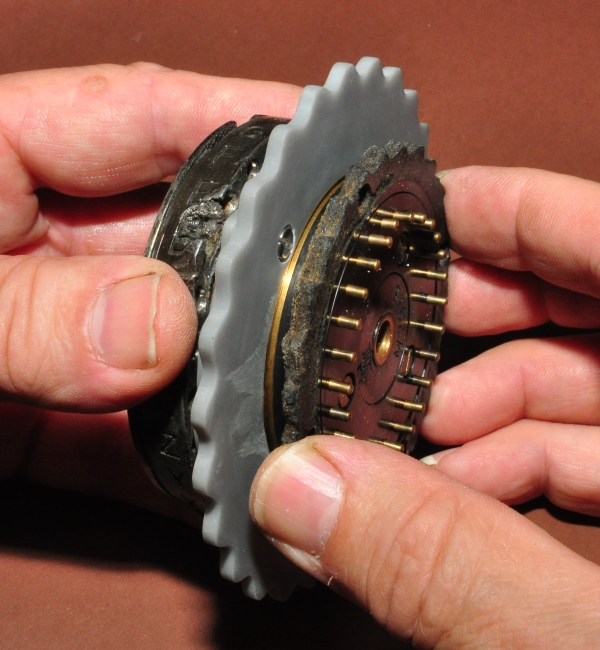

The pictures show gray 'prototype parts' produced in HDSL (High Definition Stereo Lithography) as a test for "form, fit and function". These are only temporary.

Once the prototype parts are confirmed, actual ZAMAK casts for each of the missing parts will be produced.

Thus, U85's M2946 Enigma will be 'restored' to a 'viewable' condition.

Case in point: Thumbwheels:

Anything made of the Zinc alloy, which is called ZAMAK, simply corrodes away over time in water and/or salt water.

This also happens in old cast zinc carburetors, cast radio knobs and model train parts.

The corrosion process is called "Zinc Pest" or German /'Zinkpest'/ .

(Or even "pot metal".)

German origins of ZAMAK alloys are composed:

/zink/ (zinc), /aluminium/, /magnesium/ and /kupfer/ (copper).

Sometimes low quality ZAMAK is referred to it as '/Muckite/' which containes a large percentage of lead (contaminates).

Referring to the picture, notice how the screws in the '/Ringstellung/' of the original Rotors are bent up at an angle....see special picture.

This is caused when the ZAMAK corroded and expanded forcing them into this position.

The period of time over which this happened is unclear but could have been decades.

The Base of the machine was ZAMAK and is gone also. A new Base was made in Lexan using FDM, (Fused Deposition Modeling).

The HDSL parts used in restoration are produced from drawings I made of an

original M4 Enigma.

Please sign our Guest Book

The public can see the M2946 in the Graveyard of the Atlantic Museum

in Hatteras, NC.

Here's a rare look inside the 4th rotor

Here's the 4th rotor with the test thumbwheel installed